|

Product Name

|

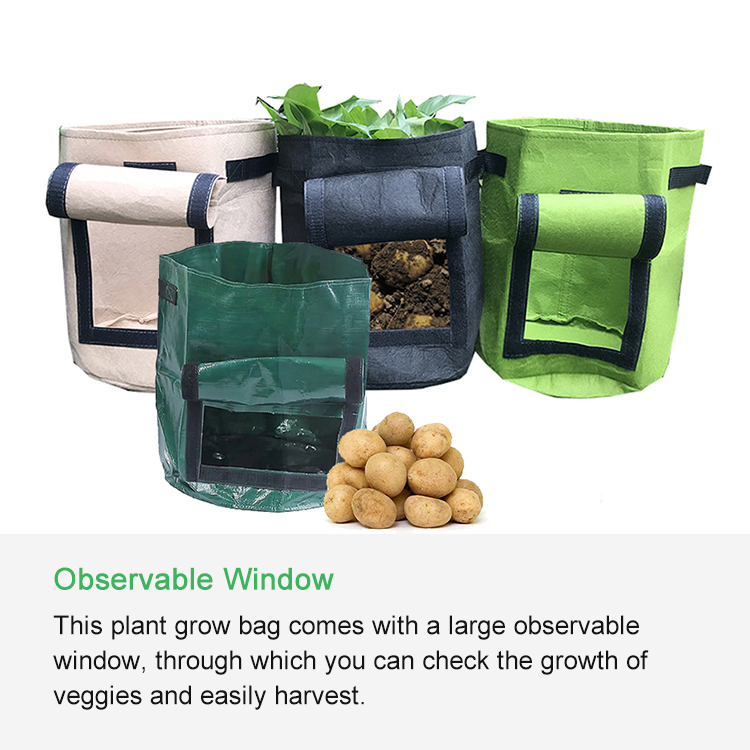

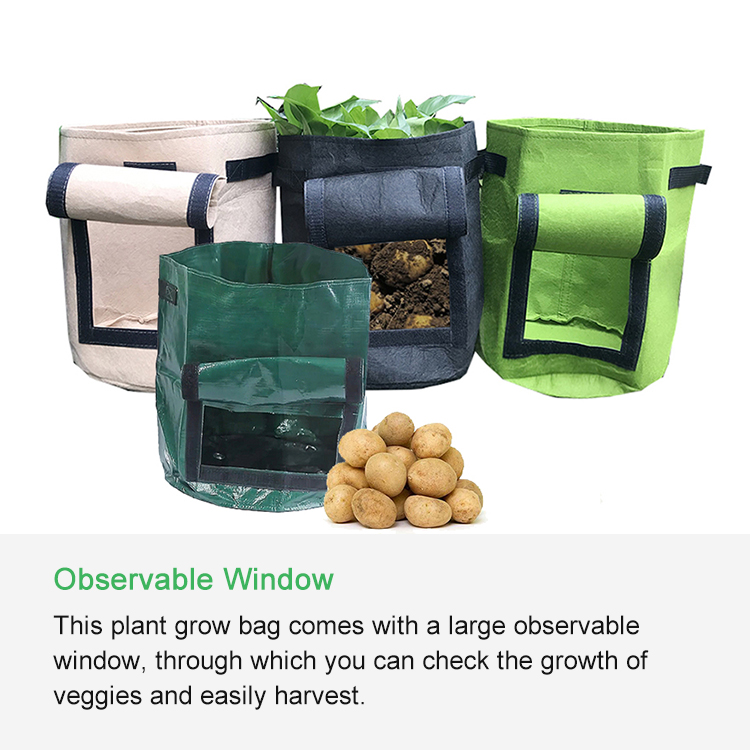

Potato Grow Bag

|

||

|

Brand

|

Sunshine Garden

|

||

|

Material

|

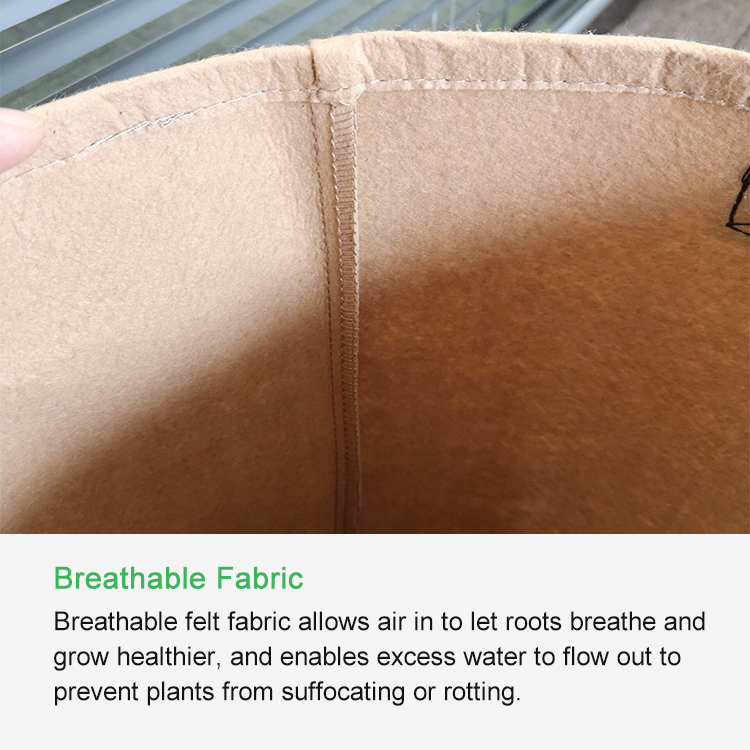

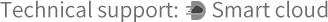

Breathable Non-woven Fabric, Dark Green PE

|

||

|

Color

|

Black, Green, Tan, Red, and customizable

|

||

|

Size

|

DiaxH(cm)

|

Gallon

|

Capacity (L)

|

|

Ø 23 * 28 H

|

3

|

12

|

|

|

Ø 30 * 35 H

|

7

|

25

|

|

|

Ø 41 * 30 H

|

10

|

39

|

|

|

Ø 35 * 45 H

|

12

|

45

|

|

Offers everything you need to build complete gardening and hydroponic systems.

.jpg) Definition of color temperature: Color temperature, measured in Kelvin (K), indicates the hue of light emitted by a lamp. It plays a crucial role in both human perception and plant growth.

Typical CMH Sodium Light ranges: CMH Sodium Lights operate between 3100K and 4200K, providing a balanced spectrum suitable for various horticultural applications.

Impact on plants and humans: Lower color temperatures (around 3100K) offer warmer, more reddish light that enhances flowering stages, while higher color temperatures (around 4200K) provide cooler, bluish light that promotes vegetative growth.

Advantages of CMH Light Spectrum

Broad-spectrum lighting: Unlike traditional HPS lamps that primarily emit yellow-orange light, CMH Sodium Light delivers a wider spectrum, including UV-A and UV-B light.

Enhanced photosynthesis: The inclusion of blue, red, and UV wavelengths allows plants to utilize light more efficiently for both vegetative growth and flowering, enhancing overall yield.

Closer to natural sunlight: The spectrum mimics the sun’s natural light more closely, reducing plant stress and producing healthier growth patterns.

Evaluating Light Efficiency

Lumens per watt: CMH Sodium Lights typically offer 80–100 lumens per watt, which is more efficient than traditional HPS lighting in similar power ranges.

Par value and photon flux: These lights deliver high Photosynthetically Active Radiation (PAR), ensuring plants can absorb and use energy effectively.

Energy-saving benefits: Higher efficiency means lower electricity consumption for the same light output, which is particularly beneficial for indoor growers managing operational costs.

Practical Implications for Indoor Horticulture

Customizing color temperature for plant stages:

Vegetative stage: Use CMH lamps around 4000–4200K to encourage leafy growth.

Flowering stage: Switch to 3100–3500K to stimulate bud formation and blooming.

Mixing CMH with other light types: Some growers combine CMH lights with LEDs or HPS lamps to fill spectrum gaps, enhancing both growth speed and quality.

Optimizing light placement: Proper positioning ensures uniform coverage, improving light penetration to lower leaves and avoiding energy waste.

Comparing CMH with Other Lighting Options

CMH vs HPS: While HPS lamps produce higher light intensity, they lack a full spectrum and may cause nutrient deficiencies or uneven growth. CMH lights provide a more balanced spectrum that reduces plant stress.

CMH vs LEDs: Modern LED systems allow precise wavelength control but may require high upfront costs. CMH offers an affordable, reliable full-spectrum solution with proven effectiveness.

Longevity and maintenance: CMH bulbs generally last longer than HPS lamps, maintaining consistent color temperature and light intensity over time, which helps reduce frequent replacements and operational disruptions.

Considerations for Optimal Performance

Ballast compatibility: Using the correct ballast ensures stable power delivery, preserving both light efficiency and color spectrum integrity.

Temperature management: CMH lights generate less heat than HPS lamps but still require adequate ventilation to prevent canopy overheating.

Regular monitoring: Checking for color shift or intensity drop helps maintain suitable plant growth conditions, as prolonged use can slightly alter the spectrum over time.

CMH Sodium Light offers versatile color temperature options and efficient light output, making it a good choice for both horticultural and indoor lighting applications. Its broad spectrum closely resembles natural sunlight, promoting healthy plant growth throughout different stages. By understanding the specific color temperature ranges, improve yield and reduce energy consumption. Compared to HPS or conventional lighting, CMH lights provide a balanced combination of quality light, energy efficiency, and long-term reliability, making them an essential tool for modern indoor horticulture.

Definition of color temperature: Color temperature, measured in Kelvin (K), indicates the hue of light emitted by a lamp. It plays a crucial role in both human perception and plant growth.

Typical CMH Sodium Light ranges: CMH Sodium Lights operate between 3100K and 4200K, providing a balanced spectrum suitable for various horticultural applications.

Impact on plants and humans: Lower color temperatures (around 3100K) offer warmer, more reddish light that enhances flowering stages, while higher color temperatures (around 4200K) provide cooler, bluish light that promotes vegetative growth.

Advantages of CMH Light Spectrum

Broad-spectrum lighting: Unlike traditional HPS lamps that primarily emit yellow-orange light, CMH Sodium Light delivers a wider spectrum, including UV-A and UV-B light.

Enhanced photosynthesis: The inclusion of blue, red, and UV wavelengths allows plants to utilize light more efficiently for both vegetative growth and flowering, enhancing overall yield.

Closer to natural sunlight: The spectrum mimics the sun’s natural light more closely, reducing plant stress and producing healthier growth patterns.

Evaluating Light Efficiency

Lumens per watt: CMH Sodium Lights typically offer 80–100 lumens per watt, which is more efficient than traditional HPS lighting in similar power ranges.

Par value and photon flux: These lights deliver high Photosynthetically Active Radiation (PAR), ensuring plants can absorb and use energy effectively.

Energy-saving benefits: Higher efficiency means lower electricity consumption for the same light output, which is particularly beneficial for indoor growers managing operational costs.

Practical Implications for Indoor Horticulture

Customizing color temperature for plant stages:

Vegetative stage: Use CMH lamps around 4000–4200K to encourage leafy growth.

Flowering stage: Switch to 3100–3500K to stimulate bud formation and blooming.

Mixing CMH with other light types: Some growers combine CMH lights with LEDs or HPS lamps to fill spectrum gaps, enhancing both growth speed and quality.

Optimizing light placement: Proper positioning ensures uniform coverage, improving light penetration to lower leaves and avoiding energy waste.

Comparing CMH with Other Lighting Options

CMH vs HPS: While HPS lamps produce higher light intensity, they lack a full spectrum and may cause nutrient deficiencies or uneven growth. CMH lights provide a more balanced spectrum that reduces plant stress.

CMH vs LEDs: Modern LED systems allow precise wavelength control but may require high upfront costs. CMH offers an affordable, reliable full-spectrum solution with proven effectiveness.

Longevity and maintenance: CMH bulbs generally last longer than HPS lamps, maintaining consistent color temperature and light intensity over time, which helps reduce frequent replacements and operational disruptions.

Considerations for Optimal Performance

Ballast compatibility: Using the correct ballast ensures stable power delivery, preserving both light efficiency and color spectrum integrity.

Temperature management: CMH lights generate less heat than HPS lamps but still require adequate ventilation to prevent canopy overheating.

Regular monitoring: Checking for color shift or intensity drop helps maintain suitable plant growth conditions, as prolonged use can slightly alter the spectrum over time.

CMH Sodium Light offers versatile color temperature options and efficient light output, making it a good choice for both horticultural and indoor lighting applications. Its broad spectrum closely resembles natural sunlight, promoting healthy plant growth throughout different stages. By understanding the specific color temperature ranges, improve yield and reduce energy consumption. Compared to HPS or conventional lighting, CMH lights provide a balanced combination of quality light, energy efficiency, and long-term reliability, making them an essential tool for modern indoor horticulture.

As a manufacturer specializing in the design and production of large plastic storage sheds, we approach this product category from an engineering and manufacturing standpoint rather than a retail-driven one. For B2B buyers, project planners, and brand owners, understanding the real advantages and structural features of large plastic storage sheds starts at the source—how they are designed, manufactured, and validated for long-term use.

Below, we outline the key advantages and functional features of large plastic storage sheds, based on our experience in large-scale plastic structure manufacturing.

1. Structural Stability Designed for Large-Format Applications

One of the core advantages of a large plastic storage shed lies in its engineered structural system. Unlike small consumer-grade sheds, large-format designs require careful consideration of load distribution, wind resistance, and long-term deformation control.

From a manufacturing perspective, this is achieved through:

Reinforced wall and roof panels with integrated rib structures

Load-bearing frame design at corners and high-stress connection points

Modular panel systems that evenly distribute structural forces

These features are not added at the retail level; they are built into the product during the design and mold-development stage.

2. Material Performance Optimized for Outdoor Environments

Material selection is a defining feature of high-quality large plastic storage sheds.

As a factory, we control material specifications to ensure:

Use of high-density HDPE or PP compounds for enhanced strength and impact resistance

UV-stabilized formulations to prevent fading, cracking, and embrittlement

Consistent material flow during injection molding to avoid internal weak points

This material-driven approach ensures that large plastic storage sheds maintain dimensional stability and mechanical performance throughout extended outdoor use.

3. Scalable Design for Industrial Manufacturing

A key advantage of plastic storage sheds at scale is their suitability for standardized, repeatable production.

From a manufacturing standpoint, large plastic storage sheds are designed with:

Modular components suitable for mass production

Mold structures optimized for dimensional consistency

Assembly systems that reduce tolerance stacking across large spans

This allows us to deliver consistent quality across large production volumes—an essential factor for OEM, ODM, and long-term B2B partnerships.

4. Low Maintenance as a Functional Feature

While often highlighted at the retail level, low maintenance is fundamentally a result of manufacturing decisions.

Large plastic storage sheds benefit from:

Corrosion-resistant materials that require no surface treatment

Integrated color-in-material solutions, eliminating repainting

Smooth, non-porous surfaces that resist moisture and mold

These features reduce lifecycle costs and make plastic sheds suitable for commercial, industrial, and institutional applications.

5. Design Flexibility for OEM and Custom Projects

As a manufacturer, one of the very important features we offer is design adaptability.

Large plastic storage sheds can be customized in terms of:

Dimensions and internal layouts

Door systems, ventilation, and roof structures

Surface textures, colors, and branding elements

This flexibility allows brand owners and project buyers to develop differentiated products without compromising structural integrity or production efficiency.

Manufacturer Insight: Advantages That Start at the Factory Level

The true advantages of large plastic storage sheds are not defined by retail descriptions, but by how the product is engineered, tested, and manufactured.

From raw material formulation to mold precision and assembly validation, every stage of production contributes directly to performance, durability, and consistency.

About Us

We are a direct manufacturer of large plastic storage sheds, with in-house capabilities covering product design, mold development, and large-scale production. Our focus is on providing stable, scalable manufacturing solutions for OEM, ODM, and B2B clients worldwide.

For partners seeking a manufacturing source rather than a trading intermediary, product reliability begins at the factory.

As a manufacturer specializing in the design and production of large plastic storage sheds, we approach this product category from an engineering and manufacturing standpoint rather than a retail-driven one. For B2B buyers, project planners, and brand owners, understanding the real advantages and structural features of large plastic storage sheds starts at the source—how they are designed, manufactured, and validated for long-term use.

Below, we outline the key advantages and functional features of large plastic storage sheds, based on our experience in large-scale plastic structure manufacturing.

1. Structural Stability Designed for Large-Format Applications

One of the core advantages of a large plastic storage shed lies in its engineered structural system. Unlike small consumer-grade sheds, large-format designs require careful consideration of load distribution, wind resistance, and long-term deformation control.

From a manufacturing perspective, this is achieved through:

Reinforced wall and roof panels with integrated rib structures

Load-bearing frame design at corners and high-stress connection points

Modular panel systems that evenly distribute structural forces

These features are not added at the retail level; they are built into the product during the design and mold-development stage.

2. Material Performance Optimized for Outdoor Environments

Material selection is a defining feature of high-quality large plastic storage sheds.

As a factory, we control material specifications to ensure:

Use of high-density HDPE or PP compounds for enhanced strength and impact resistance

UV-stabilized formulations to prevent fading, cracking, and embrittlement

Consistent material flow during injection molding to avoid internal weak points

This material-driven approach ensures that large plastic storage sheds maintain dimensional stability and mechanical performance throughout extended outdoor use.

3. Scalable Design for Industrial Manufacturing

A key advantage of plastic storage sheds at scale is their suitability for standardized, repeatable production.

From a manufacturing standpoint, large plastic storage sheds are designed with:

Modular components suitable for mass production

Mold structures optimized for dimensional consistency

Assembly systems that reduce tolerance stacking across large spans

This allows us to deliver consistent quality across large production volumes—an essential factor for OEM, ODM, and long-term B2B partnerships.

4. Low Maintenance as a Functional Feature

While often highlighted at the retail level, low maintenance is fundamentally a result of manufacturing decisions.

Large plastic storage sheds benefit from:

Corrosion-resistant materials that require no surface treatment

Integrated color-in-material solutions, eliminating repainting

Smooth, non-porous surfaces that resist moisture and mold

These features reduce lifecycle costs and make plastic sheds suitable for commercial, industrial, and institutional applications.

5. Design Flexibility for OEM and Custom Projects

As a manufacturer, one of the very important features we offer is design adaptability.

Large plastic storage sheds can be customized in terms of:

Dimensions and internal layouts

Door systems, ventilation, and roof structures

Surface textures, colors, and branding elements

This flexibility allows brand owners and project buyers to develop differentiated products without compromising structural integrity or production efficiency.

Manufacturer Insight: Advantages That Start at the Factory Level

The true advantages of large plastic storage sheds are not defined by retail descriptions, but by how the product is engineered, tested, and manufactured.

From raw material formulation to mold precision and assembly validation, every stage of production contributes directly to performance, durability, and consistency.

About Us

We are a direct manufacturer of large plastic storage sheds, with in-house capabilities covering product design, mold development, and large-scale production. Our focus is on providing stable, scalable manufacturing solutions for OEM, ODM, and B2B clients worldwide.

For partners seeking a manufacturing source rather than a trading intermediary, product reliability begins at the factory.

When evaluating storage solutions, one common question arises: Is it cheaper to build a shed from scratch or buy a premade one?

From a retail perspective, the comparison often focuses on upfront price alone. However, as a manufacturer of large plastic storage sheds, we view this question through the lens of materials, labor efficiency, structural performance, and long-term cost.

This article explores the real cost considerations behind building versus purchasing a premade shed—particularly for large-format plastic storage structures.

The True Cost of Building a Shed from Scratch

Building a shed independently may appear cost-effective at first glance, especially when material costs are considered in isolation. However, for wide-span or large-capacity structures, the hidden costs add up quickly.

From a manufacturing standpoint, self-built sheds typically involve:

Higher labor input and extended construction time.

Limited access to engineered materials and structural testing.

Greater variability in quality, alignment, and load resistance.

For large sheds, ensuring consistent wall alignment, roof strength, and long-term stability without industrial tooling or molds is challenging and often leads to higher maintenance or early replacement costs.

The Manufacturing Economics of Premade Large Plastic Storage Sheds

Premade large plastic storage sheds benefit from industrial-scale efficiencies that individual construction cannot replicate.

As a factory, we optimize cost and performance through:

High-volume material procurement with controlled formulations

Precision injection molds that ensure structural consistency

Standardized assembly systems that reduce labor time on site

These efficiencies allow premade sheds to deliver predictable quality at a lower total cost when labor, waste, and lifecycle maintenance are considered.

Upfront Cost vs. Long-Term Value

While DIY construction may seem cheaper initially, the long-term cost often tells a different story.

Premade large plastic storage sheds are designed to:

Resist corrosion, moisture, and UV exposure without surface treatment

Maintain dimensional stability over years of outdoor use

Require minimal maintenance compared to wood or metal structures

From a manufacturer’s perspective, the lower lifecycle cost is a direct result of material selection and engineered design—not a retail pricing strategy.

Scalability and Consistency: An Often-Overlooked Factor

For commercial projects, property developments, or B2B buyers, cost is not limited to a single unit.

Premade large plastic storage sheds offer:

Consistent specifications across multiple units

Predictable installation time and labor requirements

Easier logistics planning and quality control

These advantages are difficult to achieve when sheds are built individually on-site.

So, Is It Cheaper?

From a purely short-term, single-unit material perspective, building a shed may appear cheaper.From a manufacturing and lifecycle perspective, premade large plastic storage sheds are generally more cost-efficient, especially for large formats and long-term use.

The cost advantage comes not from retail markup reduction, but from:

Engineered structures

Manufacturing scale

Controlled material performance

Manufacturer Insight: Cost Efficiency Starts at the Factory

As a manufacturer, we design large plastic storage sheds with cost efficiency in mind from the earliest stages—mold design, material formulation, and structural optimization.

What end users see as a “premade product” is, in reality, the result of hundreds of manufacturing decisions aimed at balancing durability, stability, and total cost of ownership.

About Us

We are a direct manufacturer of large plastic storage sheds, focusing on product engineering, mold development, and large-scale production. Our role is not retail distribution, but creating reliable, repeatable storage solutions for OEM, ODM, and B2B partners.

When evaluating whether to build or buy, the real cost difference begins at the factory level.

When evaluating storage solutions, one common question arises: Is it cheaper to build a shed from scratch or buy a premade one?

From a retail perspective, the comparison often focuses on upfront price alone. However, as a manufacturer of large plastic storage sheds, we view this question through the lens of materials, labor efficiency, structural performance, and long-term cost.

This article explores the real cost considerations behind building versus purchasing a premade shed—particularly for large-format plastic storage structures.

The True Cost of Building a Shed from Scratch

Building a shed independently may appear cost-effective at first glance, especially when material costs are considered in isolation. However, for wide-span or large-capacity structures, the hidden costs add up quickly.

From a manufacturing standpoint, self-built sheds typically involve:

Higher labor input and extended construction time.

Limited access to engineered materials and structural testing.

Greater variability in quality, alignment, and load resistance.

For large sheds, ensuring consistent wall alignment, roof strength, and long-term stability without industrial tooling or molds is challenging and often leads to higher maintenance or early replacement costs.

The Manufacturing Economics of Premade Large Plastic Storage Sheds

Premade large plastic storage sheds benefit from industrial-scale efficiencies that individual construction cannot replicate.

As a factory, we optimize cost and performance through:

High-volume material procurement with controlled formulations

Precision injection molds that ensure structural consistency

Standardized assembly systems that reduce labor time on site

These efficiencies allow premade sheds to deliver predictable quality at a lower total cost when labor, waste, and lifecycle maintenance are considered.

Upfront Cost vs. Long-Term Value

While DIY construction may seem cheaper initially, the long-term cost often tells a different story.

Premade large plastic storage sheds are designed to:

Resist corrosion, moisture, and UV exposure without surface treatment

Maintain dimensional stability over years of outdoor use

Require minimal maintenance compared to wood or metal structures

From a manufacturer’s perspective, the lower lifecycle cost is a direct result of material selection and engineered design—not a retail pricing strategy.

Scalability and Consistency: An Often-Overlooked Factor

For commercial projects, property developments, or B2B buyers, cost is not limited to a single unit.

Premade large plastic storage sheds offer:

Consistent specifications across multiple units

Predictable installation time and labor requirements

Easier logistics planning and quality control

These advantages are difficult to achieve when sheds are built individually on-site.

So, Is It Cheaper?

From a purely short-term, single-unit material perspective, building a shed may appear cheaper.From a manufacturing and lifecycle perspective, premade large plastic storage sheds are generally more cost-efficient, especially for large formats and long-term use.

The cost advantage comes not from retail markup reduction, but from:

Engineered structures

Manufacturing scale

Controlled material performance

Manufacturer Insight: Cost Efficiency Starts at the Factory

As a manufacturer, we design large plastic storage sheds with cost efficiency in mind from the earliest stages—mold design, material formulation, and structural optimization.

What end users see as a “premade product” is, in reality, the result of hundreds of manufacturing decisions aimed at balancing durability, stability, and total cost of ownership.

About Us

We are a direct manufacturer of large plastic storage sheds, focusing on product engineering, mold development, and large-scale production. Our role is not retail distribution, but creating reliable, repeatable storage solutions for OEM, ODM, and B2B partners.

When evaluating whether to build or buy, the real cost difference begins at the factory level.

-1.jpg) Reflective Materials in Grow Tents

One of the key components in indoor horticulture is the Grow Tent Kit Accessories, particularly reflective materials. These materials play a crucial role in directing light efficiently toward plants, ensuring suitable growth and improving energy use. By understanding the function of reflective surfaces and employing proper strategies, growers can significantly improve light distribution, increase photosynthesis, and achieve better yields.

Purpose of Reflective Materials

Reflective materials in grow tents serve several essential purposes:

Enhanced Light Distribution: Reflective walls redirect light from grow lights to areas that would otherwise receive minimal exposure, ensuring even coverage across all plants.

Increased Photosynthetic Efficiency: By improving the amount of light reaching plant leaves, reflective surfaces allow plants to absorb more photons, promoting photosynthesis and healthier growth.

Energy Savings: Reflective materials reduce wasted light by keeping illumination within the tent, which decreases the need for additional lighting and lowers electricity costs.

Minimized Hotspots: High-quality reflective surfaces can diffuse light, reducing concentrated bright spots that may damage plant tissue or create uneven growth patterns.

Common Types of Reflective Materials

Grow tents utilize various materials for reflectivity, each with unique properties:

Mylar: Highly reflective and durable, Mylar is widely used due to its ability to reflect up to 90–95% of light while being easy to clean.

White Fabric (Polyester or Canvas): Provides diffuse reflection, which spreads light evenly and prevents sharp hotspots.

Aluminum Foil: Although inexpensive, it is less effective due to uneven reflection and potential hot spots; not typically recommended for professional setups.

Titanium Oxide Coatings: Used in some advanced tents, offering diffuse and high-intensity reflection for good light distribution.

Strategies to Improve Light Utilization

To improve the benefits of reflective materials in grow tents, consider the following strategies:

Maintain Clean Surfaces:

Dust, dirt, or water stains on reflective walls reduce efficiency.

Regularly wipe down Mylar or white fabric walls to maintain reflectivity.

Optimize Light Positioning:

Hang grow lights at appropriate heights and angles to ensure light hits reflective surfaces before reaching plants.

Use adjustable light hangers to shift light distribution as plants grow.

Utilize Diffusers or Secondary Reflectors:

Mirrors or secondary reflective panels can redirect light to shadowed areas.

Diffusers soften intense light and reduce hotspots, promoting uniform plant growth.

Match Reflectivity to Growth Stage:

Seedlings require gentle, diffuse light; use white reflective materials for soft distribution.

Flowering plants benefit from intense, directed light; Mylar’s high reflectivity is ideal.

Regular Inspection:

Check for tears, wrinkles, or peeling in reflective materials, as these defects reduce light efficiency.

Replace worn sections promptly to maintain consistent growth conditions.

Additional Benefits of Effective Reflective Use

Enhanced Yield: More light reaching the canopy improves flowering, fruiting, and overall biomass.

Temperature Control: Reflective walls can help balance heat by dispersing light energy more evenly.

Flexibility: A Proper reflective setup allows for multi-tiered plant arrangements without compromising light exposure.

Reflective materials are a vital element in Grow Tent Kit Accessories, ensuring that every photon of light contributes to plant growth. By selecting high-quality reflective surfaces, maintaining them, and positioning lights strategically, growers can improve light utilization, promote healthier plants, and achieve higher yields. Attention to these details ensures that the indoor garden operates efficiently, making use of both lighting resources and energy investments.

Reflective Materials in Grow Tents

One of the key components in indoor horticulture is the Grow Tent Kit Accessories, particularly reflective materials. These materials play a crucial role in directing light efficiently toward plants, ensuring suitable growth and improving energy use. By understanding the function of reflective surfaces and employing proper strategies, growers can significantly improve light distribution, increase photosynthesis, and achieve better yields.

Purpose of Reflective Materials

Reflective materials in grow tents serve several essential purposes:

Enhanced Light Distribution: Reflective walls redirect light from grow lights to areas that would otherwise receive minimal exposure, ensuring even coverage across all plants.

Increased Photosynthetic Efficiency: By improving the amount of light reaching plant leaves, reflective surfaces allow plants to absorb more photons, promoting photosynthesis and healthier growth.

Energy Savings: Reflective materials reduce wasted light by keeping illumination within the tent, which decreases the need for additional lighting and lowers electricity costs.

Minimized Hotspots: High-quality reflective surfaces can diffuse light, reducing concentrated bright spots that may damage plant tissue or create uneven growth patterns.

Common Types of Reflective Materials

Grow tents utilize various materials for reflectivity, each with unique properties:

Mylar: Highly reflective and durable, Mylar is widely used due to its ability to reflect up to 90–95% of light while being easy to clean.

White Fabric (Polyester or Canvas): Provides diffuse reflection, which spreads light evenly and prevents sharp hotspots.

Aluminum Foil: Although inexpensive, it is less effective due to uneven reflection and potential hot spots; not typically recommended for professional setups.

Titanium Oxide Coatings: Used in some advanced tents, offering diffuse and high-intensity reflection for good light distribution.

Strategies to Improve Light Utilization

To improve the benefits of reflective materials in grow tents, consider the following strategies:

Maintain Clean Surfaces:

Dust, dirt, or water stains on reflective walls reduce efficiency.

Regularly wipe down Mylar or white fabric walls to maintain reflectivity.

Optimize Light Positioning:

Hang grow lights at appropriate heights and angles to ensure light hits reflective surfaces before reaching plants.

Use adjustable light hangers to shift light distribution as plants grow.

Utilize Diffusers or Secondary Reflectors:

Mirrors or secondary reflective panels can redirect light to shadowed areas.

Diffusers soften intense light and reduce hotspots, promoting uniform plant growth.

Match Reflectivity to Growth Stage:

Seedlings require gentle, diffuse light; use white reflective materials for soft distribution.

Flowering plants benefit from intense, directed light; Mylar’s high reflectivity is ideal.

Regular Inspection:

Check for tears, wrinkles, or peeling in reflective materials, as these defects reduce light efficiency.

Replace worn sections promptly to maintain consistent growth conditions.

Additional Benefits of Effective Reflective Use

Enhanced Yield: More light reaching the canopy improves flowering, fruiting, and overall biomass.

Temperature Control: Reflective walls can help balance heat by dispersing light energy more evenly.

Flexibility: A Proper reflective setup allows for multi-tiered plant arrangements without compromising light exposure.

Reflective materials are a vital element in Grow Tent Kit Accessories, ensuring that every photon of light contributes to plant growth. By selecting high-quality reflective surfaces, maintaining them, and positioning lights strategically, growers can improve light utilization, promote healthier plants, and achieve higher yields. Attention to these details ensures that the indoor garden operates efficiently, making use of both lighting resources and energy investments.

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

-1.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features: 1. Made of environment friendly non woven fabric, allow roots breathable and healthier. 2....

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features:1) Made of environment friendly non woven fabric, allow roots breathable and healthier.2) B...

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features: 1) Made of environment friendly non woven fabric, allow roots breathable and healthier. 2)...

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features:1) Made of environment friendly non woven fabric, allow roots breathable and healthier.2) B...

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features: 1) Made of environment friendly non woven fabric, allow roots breathable and healthier. 2)...

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features: 1) Made of environment friendly non woven fabric, allow roots breathable and healthier. 2)...

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features:1) Made of environment friendly non woven fabric, allow roots breathable and healthier.2) B...

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

Features:1) Made of environment friendly non woven fabric, allow roots breathable and healthier.2) B...

Innovation Team

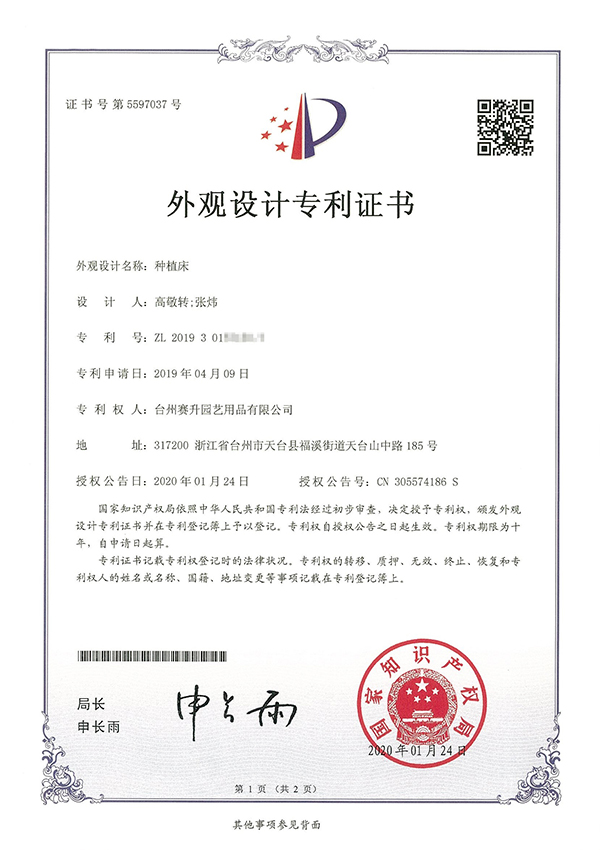

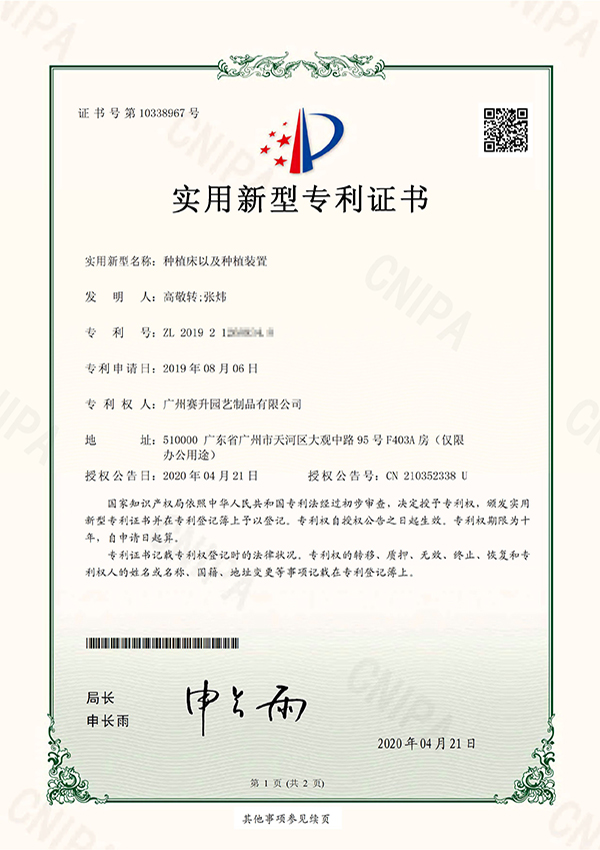

Innovation Team Patented Technology

Patented Technology Quality Assurance

Quality Assurance Efficient Response

Efficient Response

.jpg)

.jpg)

-1.jpg)

.jpg)

.jpg)

.jpg)

-1.jpg)