Sunshine Garden HPS Grow Light Series

HPS lights are good for flowering because of their red/orange output. Herbs and leafy greens may benefit from the usage of metal halide (MH) lamps.

Regardless matter whether you’re a novice or a seasoned grower, this light is an essential part of every grow room.

Growing six plants from seed to harvest will be a breeze with this lights' brightness output, spectrum, and HPS spectrums. Its dimmable ballast may reduce intensity by up to 50% when plants are young and boost peak intensity by 10% towards harvest for a genuinely personalized experience.

A domed shape and air-cooled features allow this grow lamp to optimize intensity while decreasing heat over 16 square feet of canopy.

You can adjust the light's intensity anywhere between 50% and 110%. Remove heat from a grow room by connecting to exhaust fans.

Growing six plants from seed to harvest will be a breeze with this lights' brightness output, spectrum, and HPS spectrums. Its dimmable ballast may reduce intensity by up to 50% when plants are young and boost peak intensity by 10% towards harvest for a genuinely personalized experience.

A domed shape and air-cooled features allow this grow lamp to optimize intensity while decreasing heat over 16 square feet of canopy.

You can adjust the light's intensity anywhere between 50% and 110%. Remove heat from a grow room by connecting to exhaust fans.

英语

英语 俄语

俄语 德语

德语 西班牙语

西班牙语 法语

法语

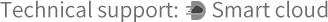

Innovation Team

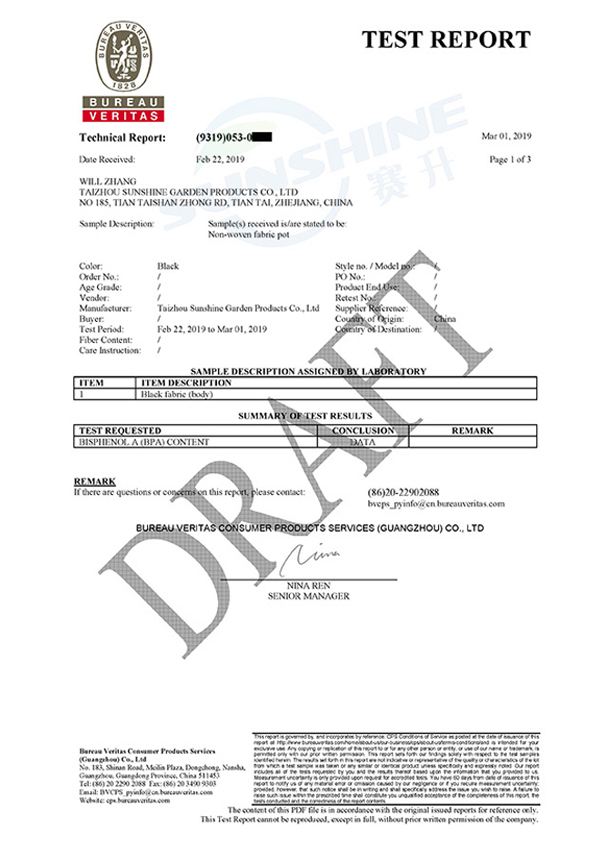

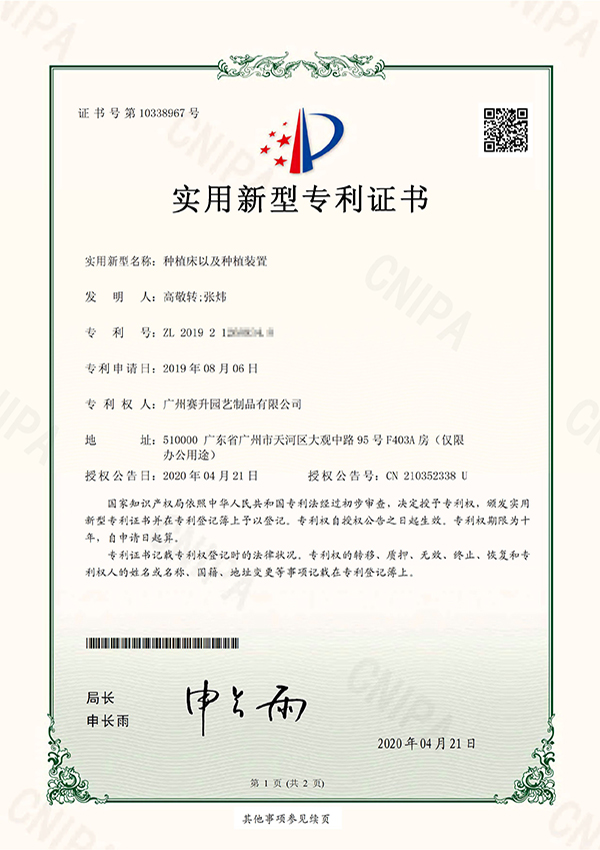

Innovation Team Patented Technology

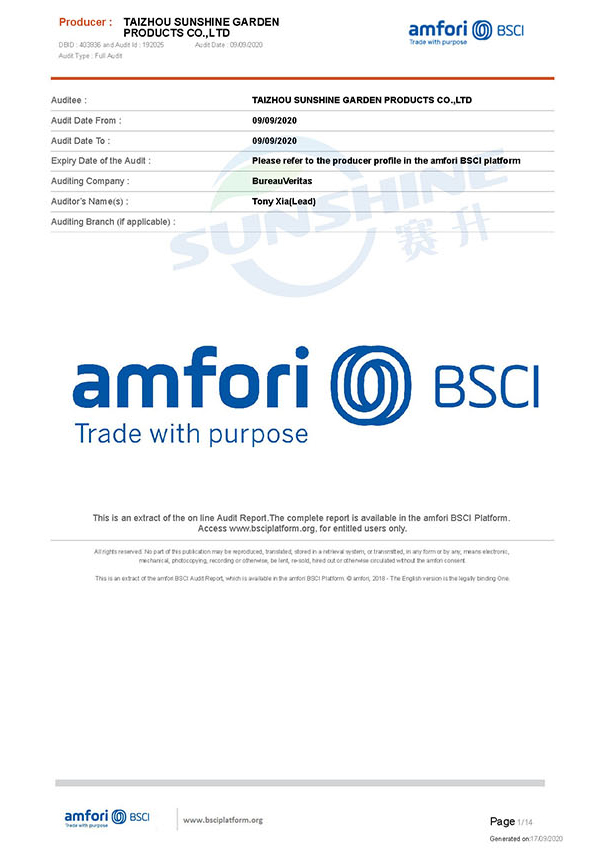

Patented Technology Quality Assurance

Quality Assurance Efficient Response

Efficient Response.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-1.jpg)

.png?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)