1. Manual drive, ease operation and movement. Seedbed border for the aluminum alloy, The surface treatment of steel pipe bracketportion and seed bed networks are hot dip galvanizing ,particularly suitable for hot and humid environment greenhouse.

2. Plant Trellis Supports are manufactured with galvanized steel to prevent rusting and corrosion. All greenhouse plant supports consist of uprights that are attached to the grow bench side rails and are connected by a rigid cross bar that has a thumb screw on each upright post for easy height adjustment.

3. The range of Trimming is 300mm, The utilize of greenhouse area is upon 80%.

4. Anti-tilt device prevent the problem of inclination caused by emphasis.

5. Using life 10-15 years.

英语

英语 俄语

俄语 德语

德语 西班牙语

西班牙语 法语

法语

Innovation Team

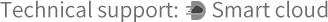

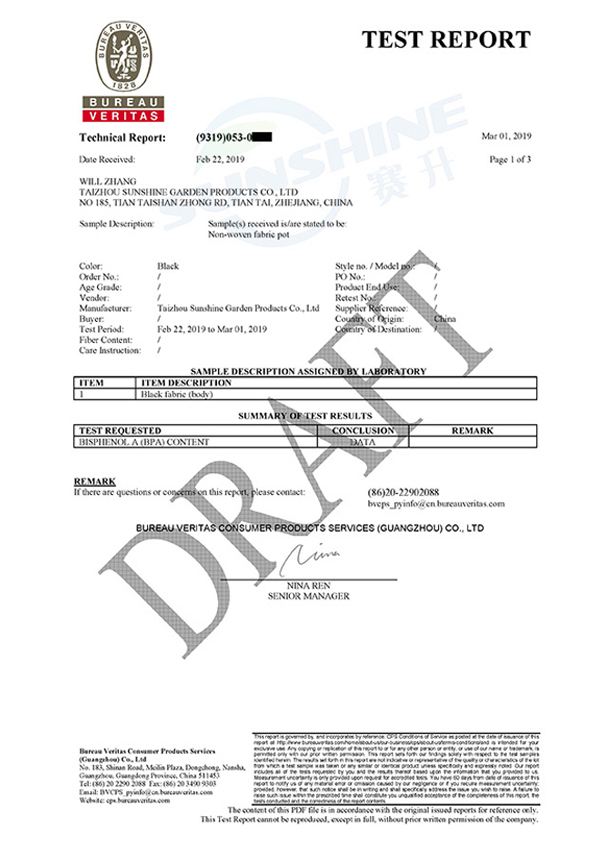

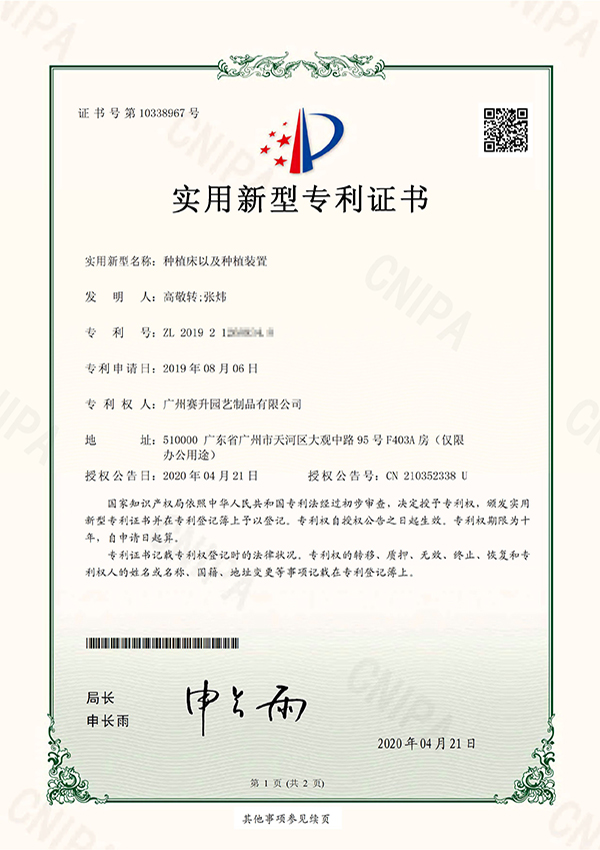

Innovation Team Patented Technology

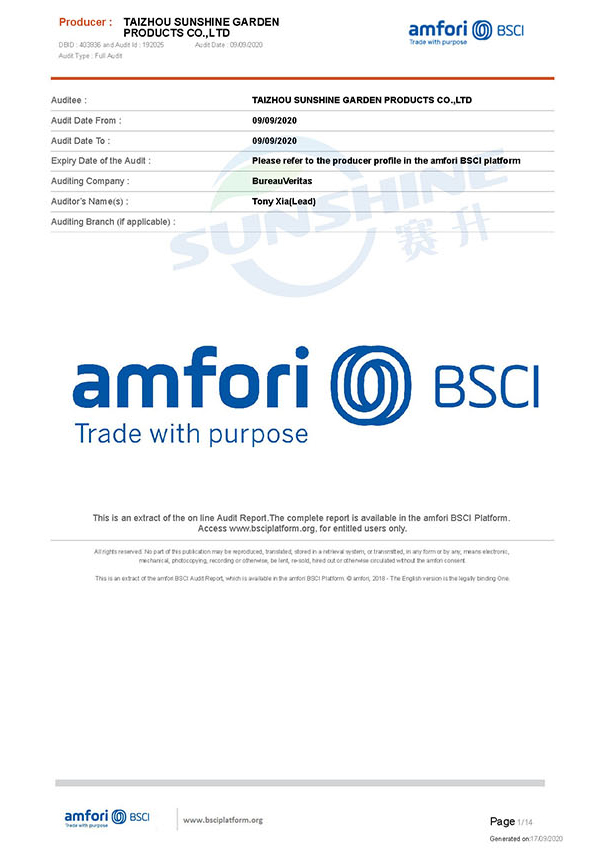

Patented Technology Quality Assurance

Quality Assurance Efficient Response

Efficient Response-1.jpg)

-1.jpg)

.jpg)

-1.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

-1.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)

.jpg?imageView2/2/w/800/h/800/format/webp/q/75)